Discover digitalization potentials

Digitalized supply chains, optimized production lines, global networking - it's not all about that. The automation and optimization of processes is the core of successful digitalization. Whether it's software, hardware or services - the key to success in the digitalization process is to take small steps that are tested again and again. As a result, more transparency and clarity can be achieved with less effort in less time - in comparison with a large long-term project plan.

Implementation according to the learning by doing principle makes it possible to test new processes and structures quickly and easily. All areas from service to accounting must be included in the digitalization process. With the help of a multimoment study, the ongoing digitalization construction sites and potentials can be identified within a few days. The possibility of repeating measurements without great effort points out the changes in structures and processes or tools used in daily work.

Not everything is digitalizable !

Not every process can be digitalized, but who knows better about this than the employees who have to perform the individual activities and tasks on a daily basis. By asking two simple questions, they can be integrated and further potentials can be discovered:

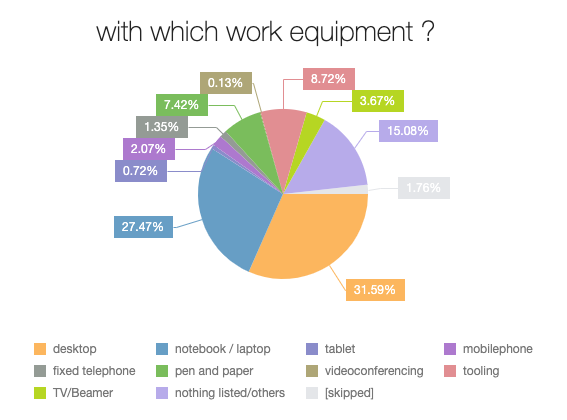

- What are you doing now?

- What are you using to do this task ?

For successful digitalization, the knowledge of all employees of the company must be integrated, because only those who carry out the processes and tasks on a daily basis can know where the optimization and digitalization potential is - and in the end, the employees also have to implement it.

Digitalization cannot be delegated - it has to be lived.